Precision Thermal Imaging for Hunting & Leisure: Premium European Solutions for ...

The Hunting & Leisure market is evolving—driven by advanced technology, changing regulations, and the expectations of a new generation of responsible hunters...

Thermography and, more specifically, infrared thermography, was originally developed for military applications. However, it has since penetrated a wide range of commercial and consumer markets. Infrared thermography can be used in many ways. But before we look at the main market applications for the technology, let’s review exactly what it is and how it works.

To understand what infrared detection is, you must first be aware that all objects naturally emit thermal energy, or heat. An animal, motor, or machine, for example, generates its own heat, either biologically or mechanically. Objects like soil, rocks, and plants absorb heat from the sun during the day and release it at night. Generally speaking, the hotter an object is, the more thermal energy it emits.

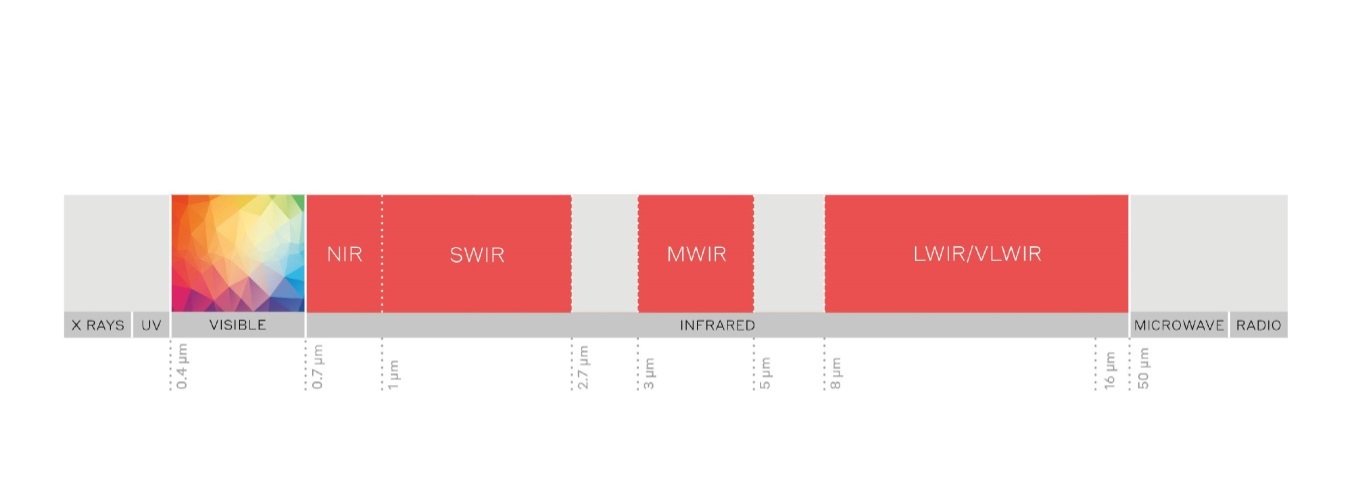

The energy emitted—thermal energy—is electromagnetic radiation that is referred to as infrared radiation. It is between the wavelengths of 0.7 µm and 16 µm, well outside the spectrum of visible light that can be seen by the naked eye.

In other words, infrared detectors can see ‟beyond” the visible spectrum as pictured in the diagram below:

The spectral region used in infrared thermography is generally from 0.9 μm to 16 μm and, more specifically, in the ranges from 2 μm to 5 μm and from 7μm to15μm.

Thermography can effectively measure the temperature of an object or a person from a distance and without touching the object or person. This is what infrared cameras do. Infrared cameras make it easy to quickly capture a thermal image that highlights the differences in temperature in the scene being observed.

Infrared thermography can be used to detect hotspots or damaged electrical wiring before a short circuit or fire occurs. Hotspots can also indicate potential equipment failures before it is too late, avoiding costly unscheduled repairs.

A faulty weld or electrical contact on a chip always causes a difference in temperature that can be detected using infrared thermography, making it a useful quality control tool.

Infrared thermography can be used for structural health monitoring (SHM).

Gas leaks are generally invisible to the naked eye. Infrared thermography can generate an image of the gas from a safe distance.

Buildings are one of the largest energy consumers around. Improving the thermal performance of buildings will be crucial to reaching environmental targets. Infrared thermography is an effective, economical way to identify faulty building insulation. The technology can be used on the ground to audit individual buildings, and in the air to audit entire neighborhoods or cities.

Infrared thermography can be used to detect elevated body temperature (fever), making it a useful tool in diagnosing potential infections. It can also detect the heat caused by inflammation. Finally, thermography is useful in diagnosing or monitoring any condition (burns) or following up on surgery (skin grafts) where circulation is an issue.

Infrared thermography can be used as a non-destructive technique for analyzing works of art. It is particularly useful at “seeing” pigments hidden deep within the layers of paint on a canvas.

Infrared technology is getting better every day. Infrared cameras are more compact and easier to use than ever. They are also more affordable. As the technology becomes more accessible, the number of uses will expand further.

Would you like to learn more? Download our infographic with our latest insights into the infrared market.